Caesars Superdome Capital Improvements

Revitalizing New Orleans’s iconic Superdome goes beyond structural integrity, it’s about rebuilding community.

the Challenge

The Caesars Superdome is an iconic symbol in New Orleans, embodying the city's resilience, culture, and spirit. Built in 1975, its design and domed structure make it a distinctive city feature. Since Katrina’s destructive path in 2005, Thornton Tomasetti has been involved in the investigation, analysis and improvements to the home of the New Orleans Saints.

Beginning with the response to Hurricane Katrina, our team assessed and documented damage to the stadium’s roof and provided litigation support on behalf of the owner. Now with the recent capital improvement work at the Superdome, we have engaged in a comprehensive and multifaceted project aimed at modernizing the stadium, enhancing the fan experience, and ensuring compliance with current standards. The work was broken into five phases and numerous “mini projects” spanning five years.

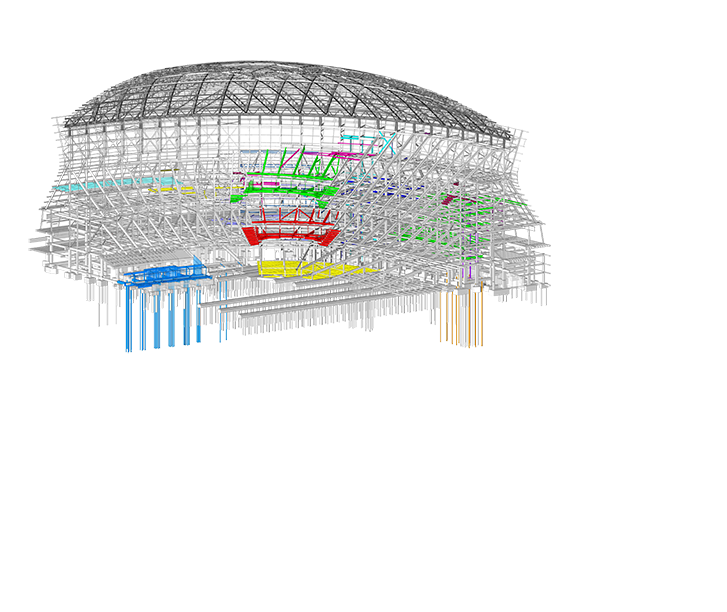

Elements included in the project were three corner atria and two sideline atria; “super-voms;” standing-room-only decks; an end zone bunker club and suites; expanded concourses and concessions; 16 new elevators as well as new escalators and egress stairs; auxiliary and away team locker rooms; and commissary and electrical substation support, among many others.

Throughout the project, the Superdome needed to remain in use, with construction work performed during the off seasons. This involved careful planning, demolition, and reconstruction to enhance functionality and capacity. A phased approach allowed the stadium to continue hosting major events, including NFL games, NCAA Final Four, concerts, and other large gatherings, ensuring a steady stream of revenue and minimal disruption to its schedule.

Here's How

A more accessible experience

Upon entering the stadium, visitors are greeted by a breathtaking view as they look up through the expansive atrium. Visitors enter at level 100 and ascend to their designated levels via newly installed escalators. To create space for the atria, we cut large openings in the existing floors, which meant reinforcing each level to redistribute lateral loads through select existing beams flying across the atrium, delivering the loads to existing vertical braced frames. At the base of the atrium, a 20-foot-deep horizontal transfer truss rerouted lateral loads around the atrium.

One of the project goals was to enhance ADA accessibility, including increased accessible seating in each of the stadium’s four corners. The continuous seating bowl presented a significant challenge, as the precast tread riser units formed an unbroken circle with small vomitories at regular intervals. The project team introduced "super voms," large openings that transform sections of the bowl into expansive vomitories, at concourse levels 200 and 500 in each corner. The design not only provided more ADA seating but enhanced the overall game day experience by connecting the concourse to the seating bowl, allowing patrons to hear the crowd and catch glimpses of the field. This was a monumental task requiring 40 existing raker trusses cantilevering 60 feet to be completely reconfigured without shoring. With close collaboration between Thornton Tomasetti, the contractor, fabricator, and erector, this work was completed at all eight locations within a single offseason, and the stadium was ready in time for the first preseason game.

The project also added 16 new elevators to enhance ADA accessibility. The challenge was that half of these elevators had to pass through the narrowest part of the building, requiring modifications to the existing structure. We needed to alter some of the facade girts in the field to allow the elevators to pass through with almost no room to spare. As the elevators reach the top, they intersect with the building's gutter system. The shafts pass through these gutters, which meant demolishing some existing precast, pretensioned gutter tubs and constructing new shafts within the space.

Collaborative approach

One of the standout aspects of the project was the close collaboration among the entire project team. Thornton Tomasetti engineers provided both structural engineering for the architect and construction engineering for the contractor/fabricator/erector. This integrated approach facilitated communication between the design team, fabricators, and erectors, ensuring that every detail was meticulously planned and executed.

On complex projects like this, an integrated approach to solving challenges is critical. We provided our Advanced Project Delivery (APD) services, which helped to achieve considerable schedule and cost efficiencies. Our construction engineering and structural design teams worked in parallel with the steel fabricator and erector to provide a fully coordinated and connected Tekla model and full shop drawings for the 2,300 tons of structural steel. With APD, the team was able to significantly accelerate the steel procurement and detailing process. After the design team reviewed and returned the shop drawings, the erector field measured for every piece of steel. Our detailers would then adjust the final shop drawings, and the fabricator would fabricate and ship the steel to the site. The entire process could be completed in as little as one week. That turn-around was only possible with teamwork and buy-in from all parties.

Thornton Tomasetti's Construction Engineering team also provided engineering support for the contractor and erector for escalator installation, elevator overrun temporary enclosure design, erection engineering and equipment loading evaluation, among other services.

Sustainability and community impact

The capital improvements to the Caesars Superdome contributed to sustainability and the community in several ways. Environmentally, it conserved resources and reduced waste by upgrading the existing structure rather than starting from scratch. Economically, it was more cost-effective, saving on the substantial expenses of new construction and maintaining revenue continuity by keeping the stadium operational during phased renovations. Socially, it preserved a vital piece of New Orleans's heritage and minimized disruption to the community. The project also provided ongoing employment opportunities, supporting the local economy and ensuring the Superdome remains a central hub for sports and entertainment.

Results

Ultimately, the project is more than just a structural upgrade: It is a testament to innovation, collaboration and the pursuit of excellence. The stadium, now equipped with modern amenities and improved accessibility, stands ready to welcome a new generation of fans, ensuring that its legacy will continue for years to come.