Ascent

The tallest mass timber structure in the world upon completion, Ascent rises 25 stories in Milwaukee.

The challenge

The Ascent, in Milwaukee’s East Town neighborhood, marked the tallest mass timber structure in the world. The 493,000-square-foot, 25-story mixed-use tower contains 259 apartments, a pool on the sixth floor and a penthouse amenity level.

Owner New Land Enterprises sought to develop a highly sustainable building that advances the mass timber industry, but this brought about challenges in terms of pushing the boundaries of prescriptive mass timber design, permitting, fire protection, and developing an efficient structure to address all the unique aspects of Tall Mass Timber design.

We provided structural design, construction engineering, and special inspection services to Korb & Associates Architects, C.D. Smith and New Land Enterprises for the project, which opened in 2022.

Here's How

Straightforward Structure

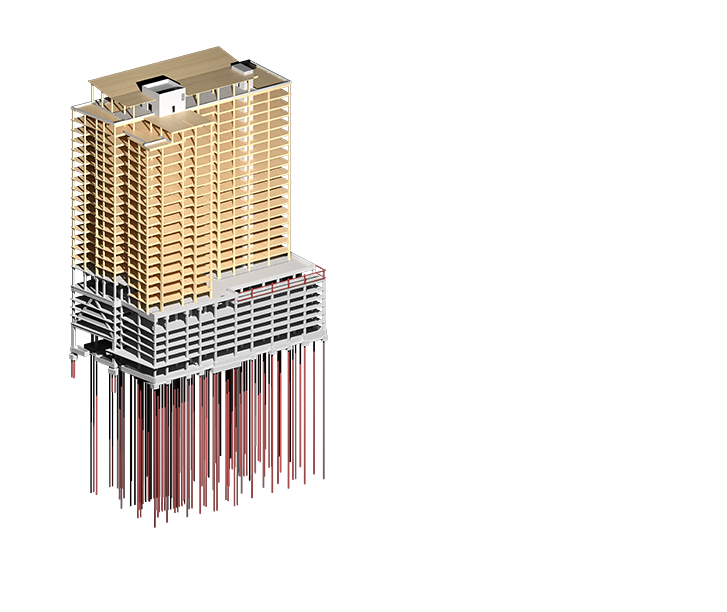

Ascent consists of nineteen mass timber residential levels, supported by a six-level cast-in-situ post-tensioned concrete podium structure, containing parking and retail at the base. A system of glulam beams and columns support one-way spanning cross-laminated timber (CLT) floors (with a gypcrete topping slab), while two reinforced concrete cores provide lateral stability.

An efficient system of post-tensioned concrete transfer beams, utilizing the structural depth provided by the pool structure and mechanical equipment, assists in merging the column grid from the timber residential floors to the concrete garage structure below. The use of post-tensioned concrete in the podium allowed for reduced floor-floor heights while addressing the environmental demands required of a parking structure located in a snowy mid-western city.

The superstructure is supported on a deep foundation system comprised of concrete-filled steel pipe piles that were statically load tested, achieving the highest capacity piles in the state of Wisconsin; reducing installation time and minimizing material quantities for substantial schedule and cost savings.

Exceeding Building Codes

Wisconsin’s commercial building code is based on IBC 2015 and its typically prescriptive design methodology. Utilizing the Alternate Materials provision, our team collaborated with and received a variance from the Authority Having Jurisdiction, allowing for a 25-story exposed mass timber structure (Type IV) showcasing the wood’s beautiful natural qualities, contingent on meeting the fire rating requirements of Type 1A construction.

Extensive fire testing, research, engineering analysis, product certifications, and select member concealment were utilized to prove that the timber structure would meet or exceed code required fire ratings, specifically the glulam beams and connections designed for a two-hour fire rating and columns designed for a three-hour rating. Additional non-structural features, including providing a fully sprinklered building and pressurizing the stairs and corridors to prevent smoke propagation during a fire, were included to enhance the fire performance of the structure.

Marking a ‘world’s first’

The code prescribed (NDS) char method was utilized to verify typical performance of the exposed mass timber; however to verify that the design meets or exceeds the fire rating requirements of Type 1A construction, additional testing was performed to confirm the three-hour fire rating for the columns. Working with the USDA's Forest Products Laboratory, located in Madison Wisconsin, the team completed the world's first three-hour column fire test for glue-laminated (glulam) timber columns.

Three species of wood—Douglas Fir, Black Spruce and Austrian Spruce—were evaluated with similar results, confirming the acceptability of the code-based char calculations for timeframes up to 3-hours. The results of the tests have been released as public information to aid in the design of future mass timber projects in North America and throughout the world.

Results

Not only does the project showcase the structural potential for mass timber along with its aesthetic appeal, but Ascent will also sequester approximately 7,200 metric tons of CO₂— the equivalent of taking 2,100 cars off the road for a year or the energy to operate more than 1,000 homes for a year—with the volume of timber fiber being regrown within ~25 minutes throughout North American forests. The lightweight mass timber construction reduced construction waste, increased construction speed and supports biophilic principles, with the wood aesthetic reducing the stress levels and increasing productivity of occupants.

While Ascent may not permanently hold the title of “world’s tallest mass timber structure”, the research, innovation, and collaboration demonstrated on Ascent will have a lasting impact on Tall Mass Timber, both in the United States and worldwide.