Sherman Minton Bridge

What if we could have investigated Minnesota’s I-35 Bridge three months before it collapsed? With the Sherman Minton Bridge, we had that chance.

The Challenge

Twelve urgent phone calls. Two worried state governments. When the contractors who were performing a retrofit of the lower bracing of the Sherman Minton bridge - which spans the Ohio River between Indiana and Kentucky in two tied arches - found a 2.5-inch crack along the bridge ties the Indiana Department of Transportation (InDoT) called us, we urged them to close the bridge immediately. Approaching autumn temperatures demanded immediate action – the cracks could easily propagate in cold weather.

What if we could have investigated Minnesota’s I-35 Bridge three months before it collapsed? With the Sherman Minton Bridge, we had the chance to prevent a similar catastrophe.

Here's How

Forensic Investigation Experts

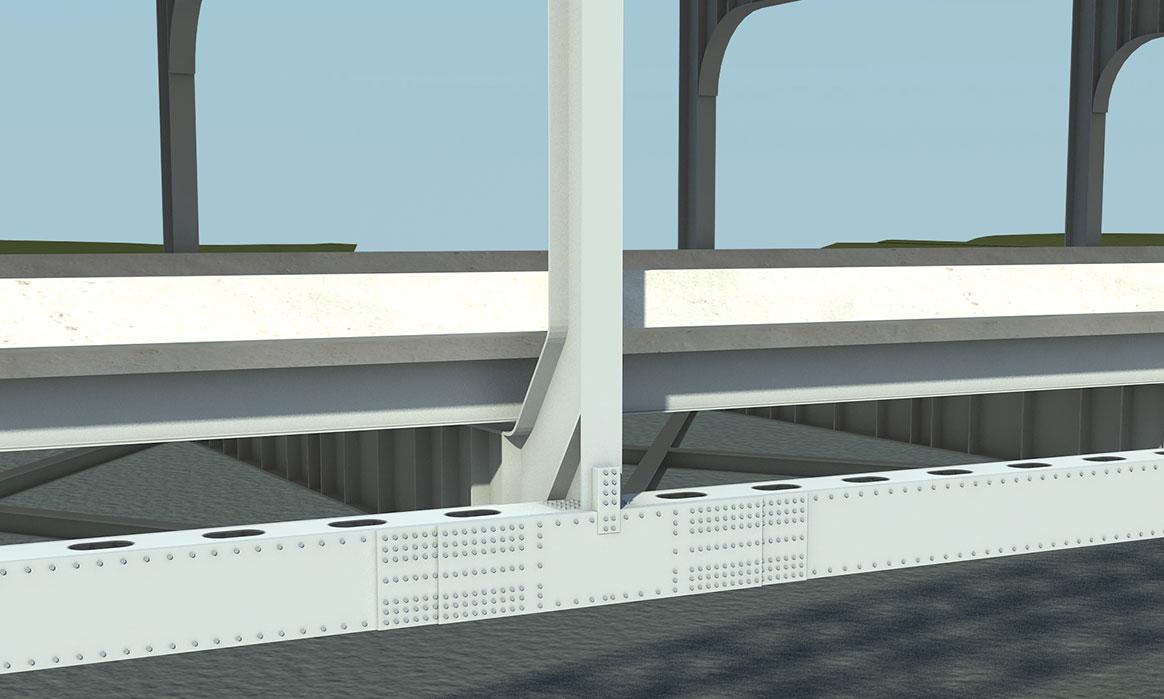

Opened in 1962, the Sherman Minton bridge has won design awards for its beauty and strength. Unfortunately, this strength also made the tie prone to potentially crack at welds, fatigue with age and fracture in cold weather. In fact, after closing the bridge our inspections identified numerous additional cracks in the steel tie. Subsequent analysis suggested that a steel tie with a large crack could fracture and cause collapsed in 20-degree weather, well above the expected temperatures of a Kentucky winter. The bridge's lower level also serves as a tie to keep the arches from kicking out, and it was along these ties that the retrofitting crew initially noticed the cracks.

The Sherman Minton bridge examination played to our technical strengths in forensics investigations. We were brought in because of our ongoing partnership with the Indiana state government following the State Fair stage collapse, as well as our recent forensic work on the I-35 bridge collapse. This time, the bridge owners were hoping to preclude another disaster. They couldn’t afford not to act. However, the technical aspect of inspecting and repairing the bridge was only part of the challenge.

Collaborative and Transparent

We were asked to lead a committee that comprised all of the relevant stakeholders. Since Kentucky and Indiana co-owned the bridge and were jointly responsible for maintenance and repairs, the committee soon swelled to around 60 people, including representatives from the governors’ offices, departments of transportation, and the city leadership from the New Albany, Indiana and the Louisville, Kentucky sides of the river. We also had contractors, the bridge consultants Michael Baker International, and independent experts from local universities advising on potential repairs. As the head of such a large committee, we played an important role in coordinating the response of different stakeholders, communicating our engineering expertise, and liaising with the public to set expectations.

Solutions Through Innovative Technology

To collate, analyze, and communicate the technical aspect of our work, we created a Forensic Investigation Model (FIM) that served as a digital portal so all stakeholders could access and follow the results of our investigation. Our team conducted non-destructive testing with ultrasonic testing, magnetic particle testing, x-rays, and radiographic testing to get a sense of where the bridge was weak and identify cracks that were not immediately visible to the naked eye. These analyses were incorporated into our FIM, which served as the visual repository for all of the data. Based on the observed weaknesses, we created sixteen different repair options and advocated for the design we thought would be most effective while allowing the committee to draw their own conclusions.

Results

The final design involved first drilling out the tips of the cracks. Where the cracks were especially large, “dog-bone” cuts intercepted the path of the cracks and prevented them from continuing to split or tear through a plate. After the crack tips were drilled out, we also recommended installing new plates along the tie with bolts connecting it to the original structure. In total, that amounted to around 32,000 bolts and our FIM also checked that the bridge had capacity for the new weight of the additional plates and bolts.

Several months and thousands of bolts later, the committee’s effective coordination and proactive response paid off. The bridge reopened right on schedule – 11:50 p.m. on February 17, 2012.