PPG PAINTS Arena

When the NHL’s Pittsburgh Penguins needed to replace their home arena, the city greenlit a $321-million multipurpose arena that utilized a fast-track project delivery approach.

Project Details

SEAKM, Grand Prize for Engineering Excellence, 2010

Hockey’s New Home for The City Of Steel

When the NHL’s Pittsburgh Penguins needed to replace their home arena – the oldest in the league – they, not surprisingly, needed it done fast. In turn, the city of Pittsburgh greenlit a new $321-million multipurpose arena that utilized a fast-track project delivery approach to make sure it was open for the start of the 2010 season. Coincidentally the Penguins won the Stanley Cup in 2009 and brought the Cup to the arena’s construction site that summer.

This wasn’t our first time enhancing the sports fan experience in Pittsburgh. In 2001 we provided structural design services to Populous for PNC Park, home of the Pittsburgh Pirates, which is a mile away from PPG Paints Arena.

We provided structural design and construction engineering services to Populous for the 720,000-square-foot complex, which opened in 2010 as the first LEED Gold certified arena in the NHL. We also provided structural design and computer modeling services for the interior stainless steel frame for “Le Magnifique,” a 4,700-lb, 12-ft statue of Mario Lemieux that was unveiled in 2012.

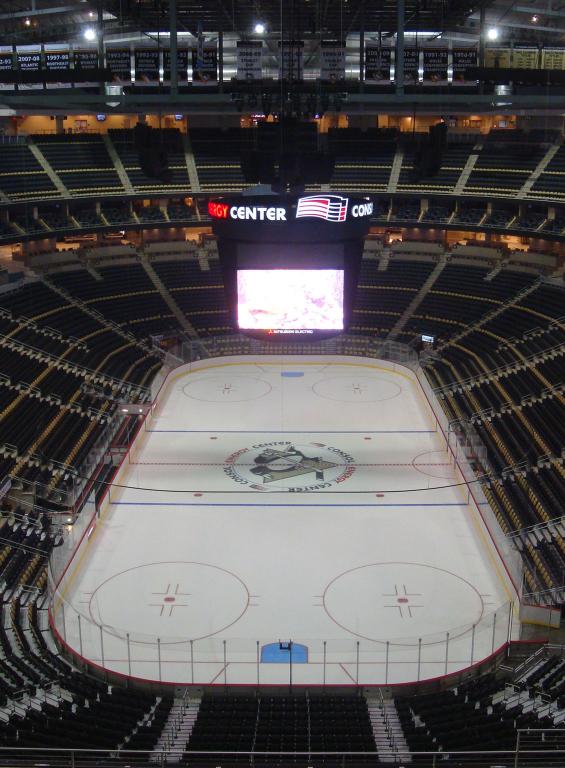

PPG Paints Arena in Pittsburgh, Pennsylvania.

Courtesy Populous

PPG Paints Arena in Pittsburgh, Pennsylvania.

Courtesy Populous

Highlights

-

The 100-foot-tall atrium space, with a dramatic spine wall along the west façade, provides a spectacular view into the concourse and suite levels of the building.

-

Not only is there an elevation change across the site, the building is cut into and is founded upon bedrock at the north end of the site and drilled piers extending through almost 30 feet of “unconsolidated fill” at the south end.

-

Controlled low-strength materials were utilized as backfill behind a 28-foot-tall by 500-foot-long basement wall, reducing vertical and lateral earth pressures and settlement, creating retail space along the entire south end of the arena.

-

The interior view of the roof is unique since all catwalk and rigging girds have been placed at the top chord of the two tied arch trusses, leaving the plunging tension tie prominently exposed. This element enhances the interior view, while significantly simplifying the structural steel construction.