Pittsburgh Int'l Airport Terminal Modernization

The modern world is on the move. To keep up with millions of air passengers today means building an airport for tomorrow.

Project Details

The Challenge

As the second-busiest airport in Pennsylvania, Pittsburgh International Airport (PIT) sees a lot of passengers. That traffic now relies on an automated people mover (APM) to get from landside to airside and back again. A modernization program will connect passengers directly and provide a more comfortable arrival and departure process. The $1.3 billion plan also includes renovations to existing airside concourses to seamlessly connect them to the new terminal.

The project was also an opportunity to envision the airport of the future. What does it look like? How can it perform? We can’t eliminate the inevitable flight delays and cancellations. But we can make the overall passenger experience more pleasant. We also had to find a way to keep people moving during construction of the new building, which is right above the underground APM station and tunnels.

Courtesy Gensler + HDR in association with luis vidal + architects

Courtesy Gensler + HDR in association with luis vidal + architects

Here's How

Nurturing Nature

Today, building performance is closely tied to occupant comfort, health and wellness. For PIT’s new terminal, the design team used biophilic design to bring nature into the building wherever possible. We tapped into building science, benchmarking other major airports and closely analyzing typical behavior patterns.

Raising the Roof

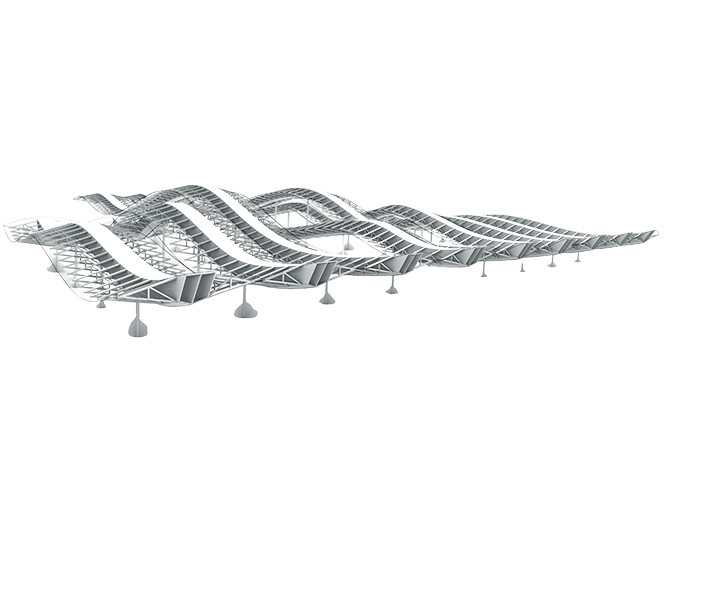

A lightweight, long-span roof is composed of independent, waving ribbons, with an exterior form that mimics surrounding hills. Within, it provides a forest-like canopy with pockets between ribbons diffusing natural light into the space.

We worked closely with the architectural team and our CORE modelers to swiftly model many iterations of the undulating roof surface to find an efficient structural geometry that met both functional requirements and aesthetic goals.

Tree-shaped steel columns support the roof. Our CORE modeling experts used genetic algorithms to identify the grouping of angles that minimized number of unique column “branches” to simplify fabrication.

We also modeled realistic environmental conditions, such as wind-driven rain, to inform the most effective size and shape for the canopies.

Ready, Aim, Fire

Innovative performance-based fire engineering offered a triple benefit: fire safety, improved aesthetics and lower construction cost. How? We modeled several realistic fire scenarios and analyzed how they affected the hollow steel columns. Why? To prove that filling the columns with concrete makes them so strong they don’t need standard fireproofing coatings.

We collaborated closely with local safety authorities to clearly show how our design meets the code’s intent. The outcome? They approved the code variance.

Seeking Security and Sustainability

Security is a key driver in the design of every airport terminal. A threat, vulnerability and risk assessment (TVRA) focused on predicting and mitigating the full range of potential human-caused and natural hazards and provided a range of reasonable and proportional physical, technical, and operational security options.

To advance PIT’s goal for greenhouse-gas emissions reduction – of 20% by 2028 – the new building is targeting LEED Silver certification. Advanced digital modeling helped us optimize structural systems and materials to maximize efficiency. The team also chose locally sourced timber, no-VOC coatings and paints, and glazing that admits abundant daylight but minimizes glare.

Foundation Finesse

The new terminal’s foundations couldn’t disturb the underground APM station directly below. The solution? Replace the existing soil and concrete paving above the APM with high-density geofoam to add load capacity that would allow building directly above the active station.

Results

The 811,000-square-foot PIT landside terminal is scheduled to open in 2025. A sustainable, secure and accessible space that supports responsible operations, the two-story, building will ease congestion and improve the health and wellbeing of workers and travelers.