Engineering for the Water Industry

We use bespoke computational fluid dynamics methods to optimise the design of a variety of water treatment equipment and systems.

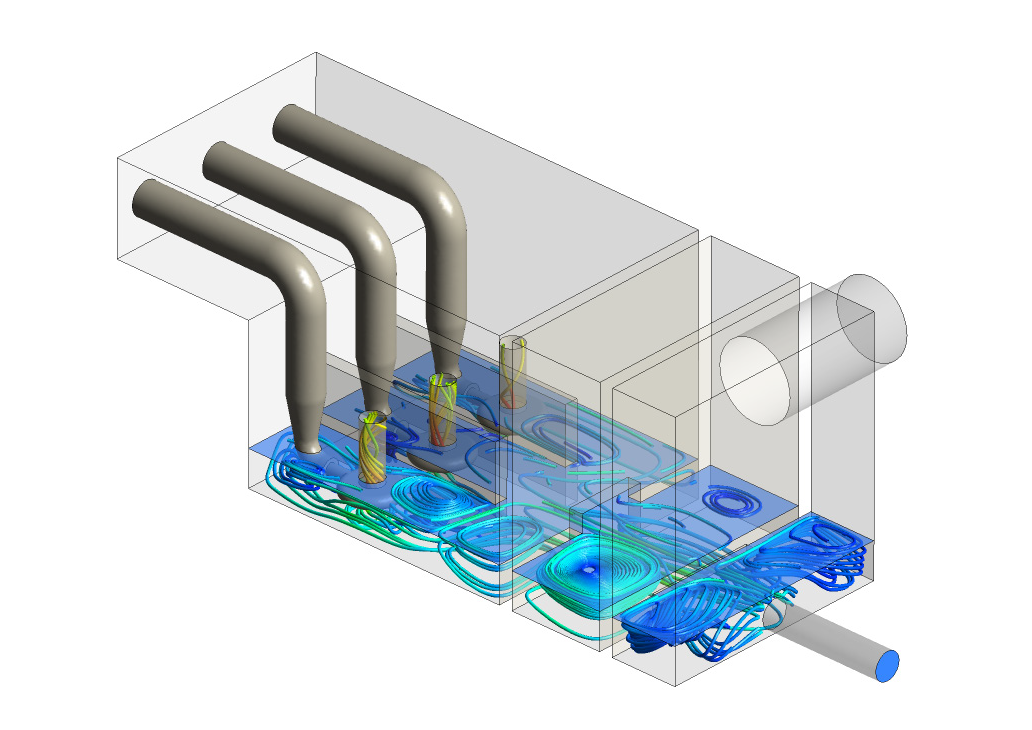

Streamlines showing non-uniform approach flow in a series of pump bays.

Thornton Tomasetti

Streamlines showing non-uniform approach flow in a series of pump bays.

Thornton Tomasetti

Chen Heng Kong / Shutterstock

Chen Heng Kong / Shutterstock

Computational Fluid Modelling Expertise

At Thornton Tomasetti, we help water industry clients optimise assets with minimal disruption and expenditure. We leverage specialized expertise in computational fluid dynamics (CFD) to deliver tailored analysis for the design of water treatment equipment and systems, with a strong focus on both clean water and wastewater applications:

Clean Water Applications

- Contact Tanks

- Network Modelling/Flow Distribution

- Ozone Tanks

- Pump Sumps

- Reservoirs

- Service Reservoirs

- Surge Analysis

- Ultraviolet Disinfection

Wastewater Applications

- Aeration Lanes

- Anaerobic Digesters

- CSOs/Storm Tanks

- DSEAR (Dangerous Substances & Explosive Atmospheres Regulations) Assessments

- Final Settlement Tanks

- Flow Load Balancing

- Phosphorous Removal

- Primary Tanks

- Surge Analysis

Activated Sludge Plant (ASP) Treatment

Anoxic Zones & Aeration Lanes

We use CFD to accurately assess anoxic zones and aeration lanes, including the performance of aerators within the lanes.

Our methods allow resolution of solids distribution and impeller action on the flow, while dye-trace analysis can determine residence time distribution and degree of short circuiting.

Flow pattern through anoxic zones.

Flow pattern through anoxic zones.

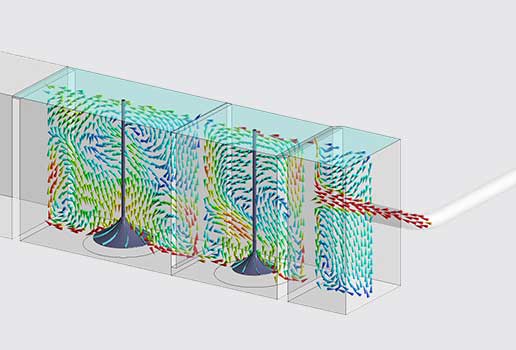

Final Settlement Tanks

Final settlement tanks (FSTs) clarify the final effluent at activated sludge plants. The flow through a final tank is not one-dimensional and will exhibit non-ideal flow behavior, such as flow recirculation and short circuiting, so the actual settling performance will usually be less than predicted by mass flux theory (MFT).

CFD can be used to assess the internal hydrodynamic performance of existing or new tank designs. We can opitimise tank geometry or the inlet arrangement – by inclusion or adaptation of stilling wells; energy dissipation influents; or baffles, such as the McKinney baffle – to improve effluent quality.

Example of solids concentration contours at a final settlement tank.

Example of solids concentration contours at a final settlement tank.

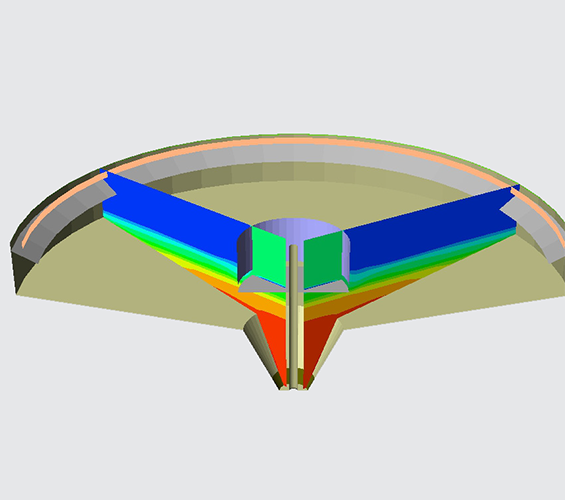

Storm Tanks & Combined Sewer Overflow (cso)

CSOs are used to spill storm water during heavy rainfall, while storm tanks act as a source of capacitance, storing storm water until the storm load subsides. Both systems should allow the flow to spill with minimal loss of solids.

Storm tank vac flush modelling.

Storm tank vac flush modelling.

Our team uses CFD to assess the effectiveness of a CSO or storm tank at retaining solids. We also undertake preliminary assessments of vac flush systems used for flushing solids from storm tanks and of hydroejectors that homogenise solids during drain down.

Surge Analysis & Network Flow Distribution

Surge protection is typically achieved through surge vessels on the suction and delivery side of pumps. We use computational pipe-network models to determine transient pipeline pressure, and we define the volume, dimensions and connection details to the rising main.

Surge Valves

We also design more bespoke systems that use surge-relief valves or pressure-sustaining valves and utilise existing equipment. This keeps transient pressures from exceeding the pipeline rating and dropping below atmospheric pressure, which could result in ground-water ingress. Our surge analysis team have extensive experience in the use of surge analysis software packages to solve problems associated with equipment operation, such as pump start-up/stop trip, valve actuations and pipe failures.

Vital Hill / Shutterstock

Vital Hill / ShutterstockNetwork Flow Distribution

Computational analysis forms an essential part of water distribution network management. Our CFD methods identify operational issues, such as shortfalls in supply or depleting reservoir levels.

And we can use the same analysis techniques to optimise operation and cost, as well as the design of network extensions.

Alex Stemmer / Shutterstock

Alex Stemmer / ShutterstockContact Tanks

A good contact tank design depends on its ability to promote plug flow, which provides water of uniform treatment quality to a domestic water supply. We use CFD techniques to generate detailed information about flows, residence time distribution (RTD) and chlorine degradation in water treatment systems:

- Water Age: We generate the basic hydrodynamics from a 3D model of the tank’s geometry. A simple age scalar can be used to emphasise the presence of flow recirculation and quiescent regions.

- RTD: Dye trace studies can be replicated in a CFD calculation and used to compare designs via different indices that define mixing characteristics, such as t10, and the number of tanks in series.

- Chlorine Decay: We can also calculate the transport of a disinfectant such as chlorine and include a decay model to determine, for example, the amount of residual chlorine at the discharge from the contact tank.

Facility Resilience

In addition to providing CFD modelling expertise, our firm also performs multidisciplinary assessment and recovery-based design services that improve the long-term resilience of water treatment facilities.

Resilient and reliable infrastructure is crucial to keep services and critical systems functioning. See how Thornton Tomasetti drives the iterative process for infrastructure risk and resilience evaluations to guard against natural, climatic and human threats.

One example of facility resilience is the North River Wastewater Resource Recovery Facility (NR WRRF), operated by the New York City Department of Environmental Protection since it opened in 1986, which handles 125 million gallons of wastewater daily in dry weather. The plant is located along the Hudson River with Riverbank State Park built atop its 28-acre footprint.

The aging facility has experienced structural deterioration that has impacted many components of the plant, such as complex drainage systems and expansion joints, leading to leaks that create difficult working conditions for plant operators and disrupt efficient operations.

We provided structural engineering and flood resilience services to revitalize the NR WRRF so it can continue to operate safely and efficiently. Our engineers evaluated the condition of the facility’s structural components and recommended repairs and replacements as needed.

Because the NR WRRF experienced significant flooding in 2012’s Superstorm Sandy, our flood-resilience engineers have been tasked with value engineering to improve the plant’s drainage and roofing systems. This includes evaluating drainage capacity for the heavy rainfalls expected in the future and assessing backflow-prevention systems to account for anticipated sea-level rise and projected flood elevations.

Contact Us

Our Warrington office, established in 2002, employs nearly 50 engineers, physicists, mathematicians, scientists, and support staff. For nearly 20 years, we have partnered with water and wastewater clients to deliver detailed analyses of treatment processes that enhance the efficiency of existing facilities and optimise the design of new ones. The seven experts on the Warrington thermofluids and CFD team bring over 50 years of combined experience to solving complex challenges for our clients.